Hi, I am going to tell you a long case about how we did BMS of the shopping mall within 5 years, output all engineering systems to 3 computer displays and made beautiful interfaces for them.

Firstly, I’m going to say what BMS is and why it’s needed, especially for a shopping mall. BMS or Building Management System – is a smart house, but in the scope of big buildings and constructions. As in a smart house, everything is incorporated into one system, where it’s possible to monitor and control the light, climate, etc. BMS in such big spaces solves 2 most important problems. First – is to immediately identify and react to failures. If something is broken, a leakage, heating is disrupted in winter, light turned off, the staff should immediately know about it. Second – is the reduction of service time. To turn off the light in the shopping mall without BMS, a technician has to visit all electrical boxes and turn off the light, which takes about 4 working hours, you can imagine, how they lived and how much time they spent without BMS.

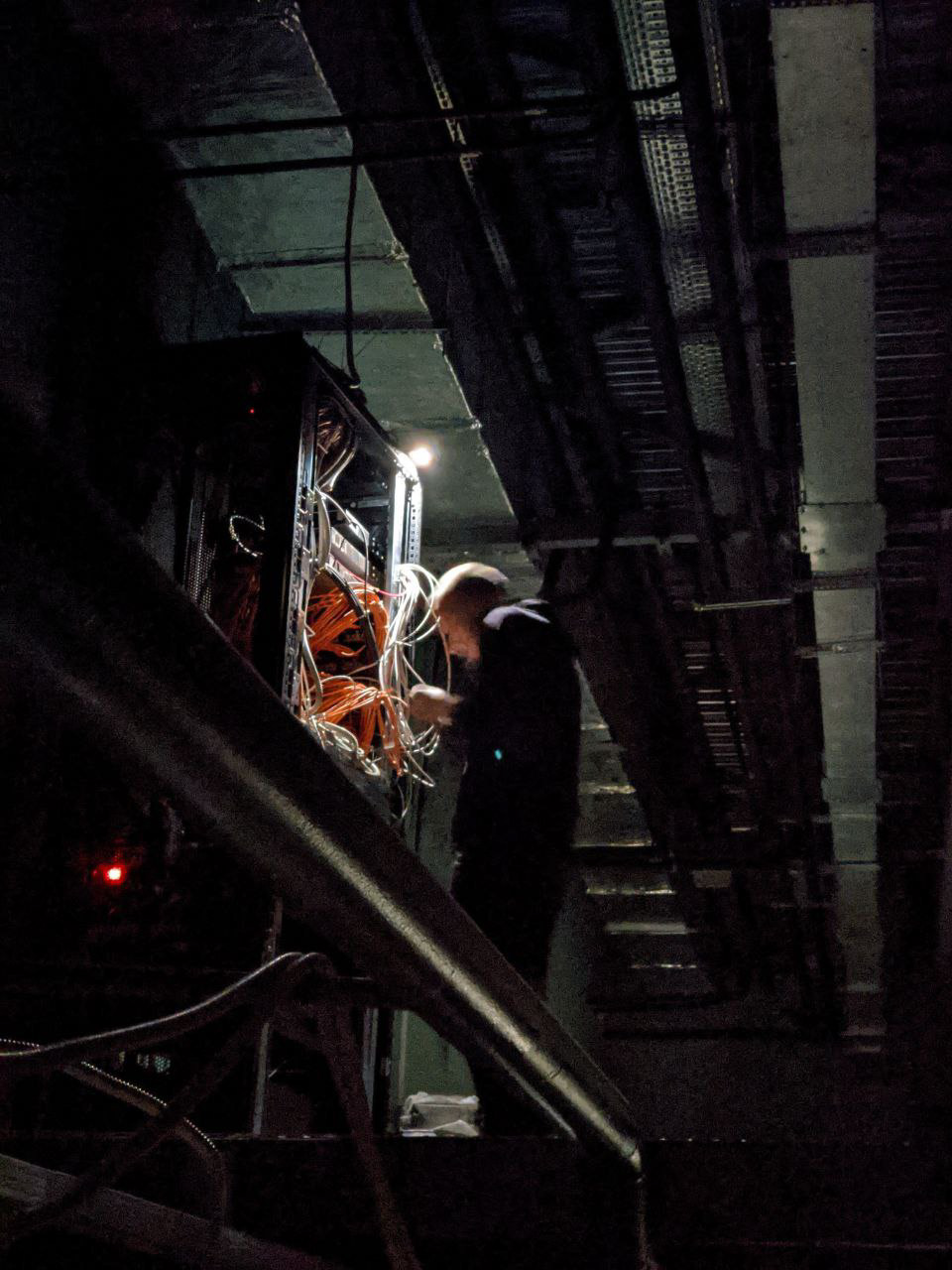

Let’s recall, that it was an operating shopping mall with really plenty of systems in it. Many works could only be carried out at night. At the first stage, we needed to get 98 HVACs, 60 exhaust units, 7 individual heat supplies, 156 FCUs and about 30 lighting panels into BMS. We signed a contract and started the works.

Lighting

The client asked us to start with the lighting, as it was the biggest sore thumb of the whole shopping mall. All in all, about 30 lighting panels and 270 light lines, and all this information was to be placed into one display, preferably conveniently, beautifully, informatively and clear to any person. There were no ideas, that was why I started trying different possibilities.

I put the AutoCAD planning into 3D Max, raised the walls and tried to show the light. The idea, maybe, would have worked, if there had been only a couple of lamps and not so many corridors and so much space. There, however, we had decorative lighting and glass roof lighting and many other things, which we had no slightest idea how to show. It was unclear how to hide walls to be able to see the farther corridors. In short, the idea wasn’t very good.

I tried to leave the pseudo 3D and make a top view. Much better, it allowed showing much more. In the picture, you can see a turned-off decorative lighting and a point light at the entrance area. The idea was livelier, I could have spent much time and could have drawn it all beautifully, but it would have been hard to make it informative, as there would have been many lines and it would have been hard to find the necessary ones. Moreover, we needed to keep in mind, that except lighting, there would be many other windows, and we needed to maintain the common style. This is one of the reasons why I stopped using 3D in interfaces long time ago, it’s hard to scale and keep the identity.

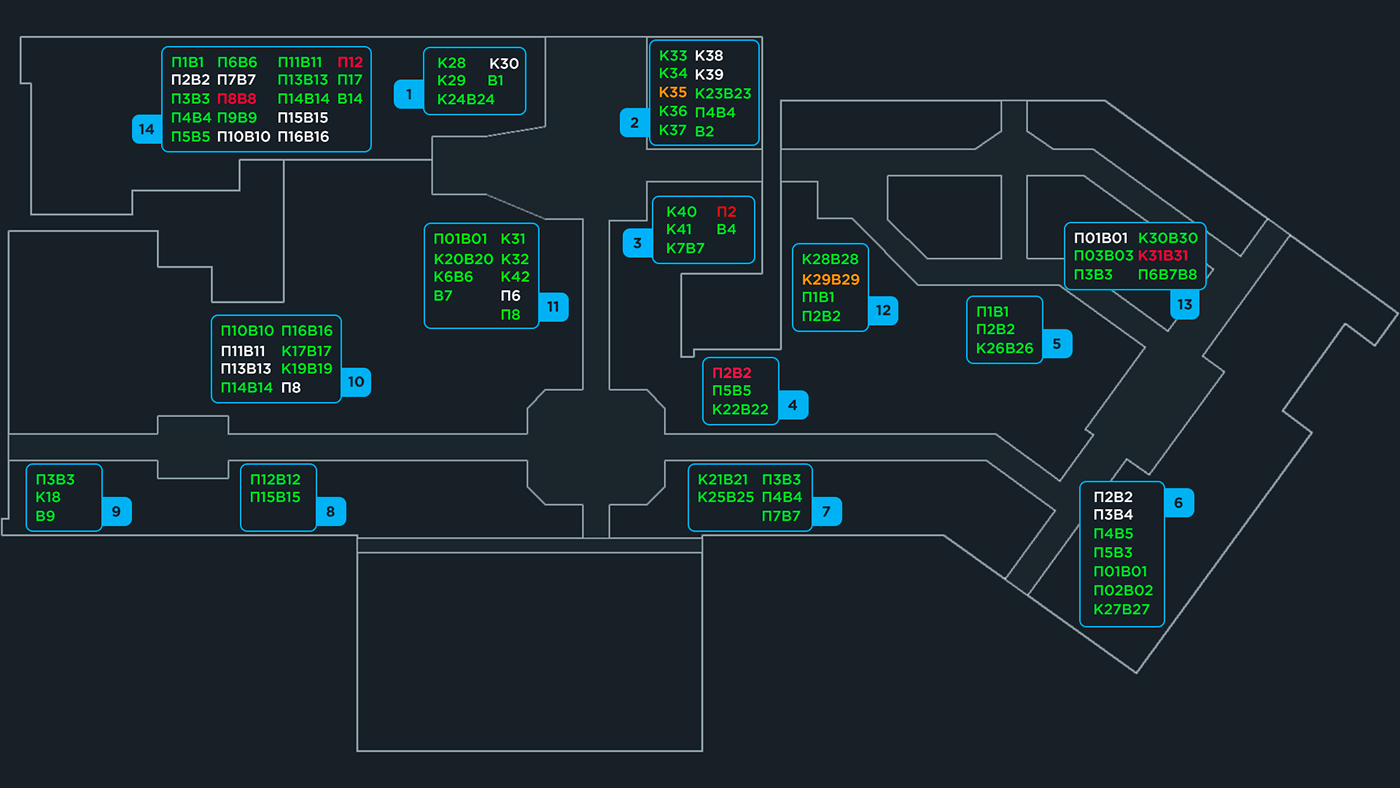

I liked the idea to leave the shopping mall layout and place the information on it, besides, it fitted into the display size very well. And, most importantly, the shopping mall was one-floor, with two or more floors the case would have been different. In the screenshot above, I tested how to place ventilation on the plan so that it could all fit in, and I had an idea to make it simple and clear to the maximum, group the installations by ventilation rooms, and lighting lines by control panels. And output only the installation name or lighting lines into the main display, and put the name into the needed color depending on the condition. The idea was great. I just needed to polish and adjust it.

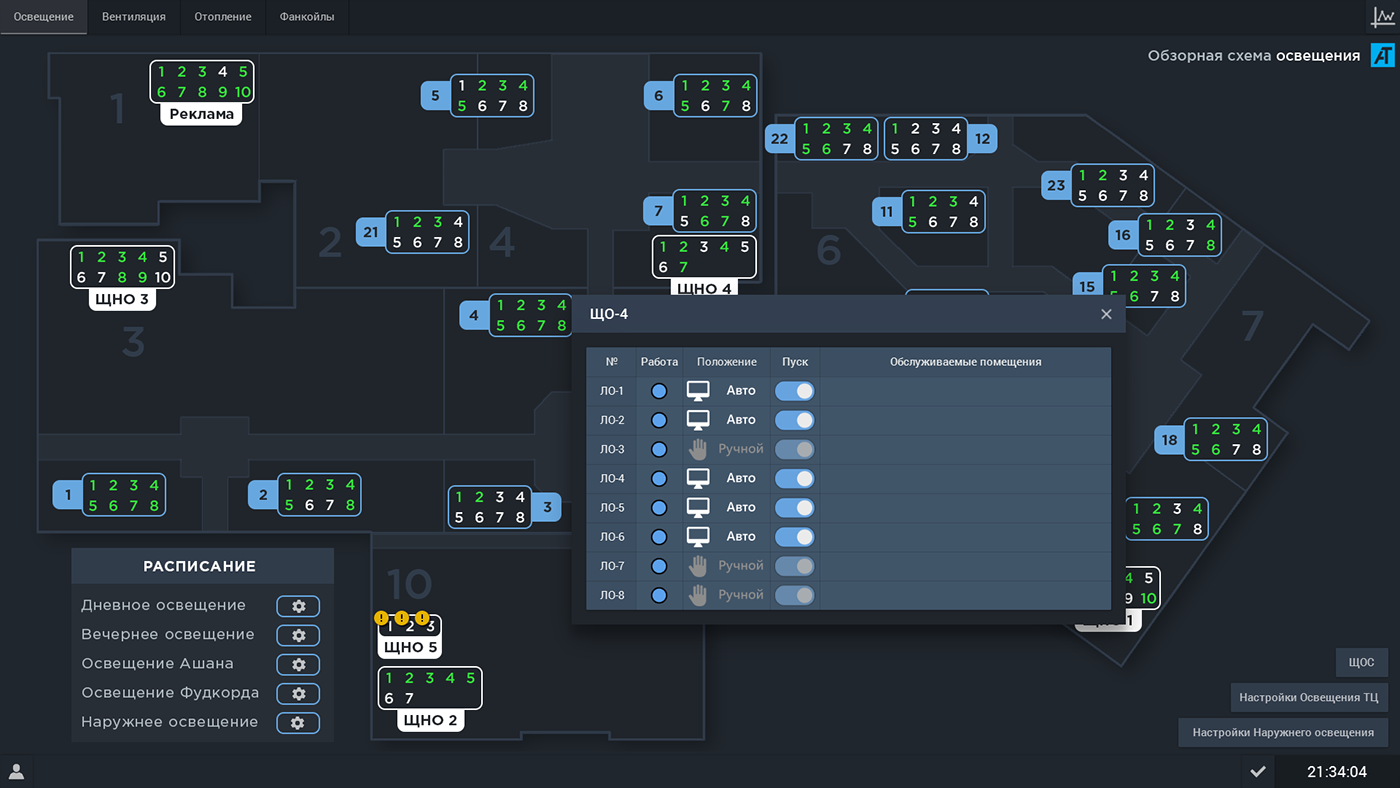

There you can see a fully working proposal, the colors are picked, the names of the sections are made, the galleries are specified and the shadows are added. Each blue box − is a lighting panel, in there it has lighting lines. White color – means turned off, green – turned on, red – faulty line. Faulty line means that it’s either haven’t turned on or haven’t turned off. We made several different schedules for different types of lighting. All the panels on the screen are clickable, a detailed window opens each time with a click.

A sub-window contains more information about the line, here it has its number, status, operating mode and a comment.

Ventilation

Having done the lighting, we had the concept for the main display for ventilation and other systems, it calmed us down a bit, we understood from what we should start. On the other hand, there were 98 ventilation machines on the rooftop with controllers, including lighting, with which we hadn’t worked before. By the time of our visit, the automation had been fully ready, the ventilation had been working full time, but, anyway, we needed to change the algorithm, as we needed to additionally install the frequency converters for Modbus RTU into the controller. The idea was to create one fully refined algorithm, master it and then multiply it to all the installations.

In 2020 we transferred absolutely everything to templets, now we have templets inside templets inside templets, that is why applying changes takes up only a few minutes. Nevertheless, the most useful templets function – is the minimization of errors and spelling mistakes. In 2018 we created and binded more than 10,000 variables, no matter how much we had tried, it was impossible to avoid mistakes.

In the lighting interface we had one level of pop-up windows, yet the ventilation had much more information, so we decided to create two levels of pop-up windows. By clicking a ventilation room a window would open, containing vital parameters of the entire installation of this ventilation room, and by clicking on the particular installation a scheme of the particular installation would open.

Heating

The shopping mall had 7 individual heating supply stations, we did them, ventilation and FCUs simultaneously.

The heat supply stations interface was made quickly, as we had already used the groundwork from the ventilation.

FCUs

We had more questions about FCUs, and they were the most complicated part. What was wrong?

1. All FCUs were stationed 6 meters above the floor.

2. Almost all FCUs were stationed at the leaseholders’ territory, where we needed to approve the access for off-hours.

3. Some FCUs were completely non-accessible.

4. A whole pack of FCUs with cut offs due to unclear reasons. Maybe there was no power, maybe a controller or a fuse had burnt out, and maybe it was a loose wire.

5. One line with 15 FCUs had broken down a long time ago and nobody knew what was wrong with it.

Everything is clear about the interface, the universal primary version is very easily scaled to any system.

Power engineering, lead-in distributors, transformer substation

We did BMS for 6 electrical cabinets and 1 transformer substation. There was preparation for BMS, but there was no documentation and all the wires had to be tested again and we had to put everything in order. From each electrical cabinet we registered alarms and status control in inputs and sections. In both inputs there were digital multi-meters, via them through the interface we registered actual measures for voltage, current and capacities. We made some reports on voltage and current consumption, sometimes they could come in handy. We were asked to only register overcurrent from the substation.

Sewage pumping stations, downpour drain stations, local sewage disposals, heat curtains, rooftop heating

There were a whole lot of different signals, so we decided to output it all into one display in order not to have too many displays.

Rooftop and drain outlets heating. Each heating had its own small panel with Pixel and street temperature detector, we wrote the new management program.

Refrigerating center

The shopping mall had 2 refrigerating centers with serious equipment and own automation system with controllers Carel.

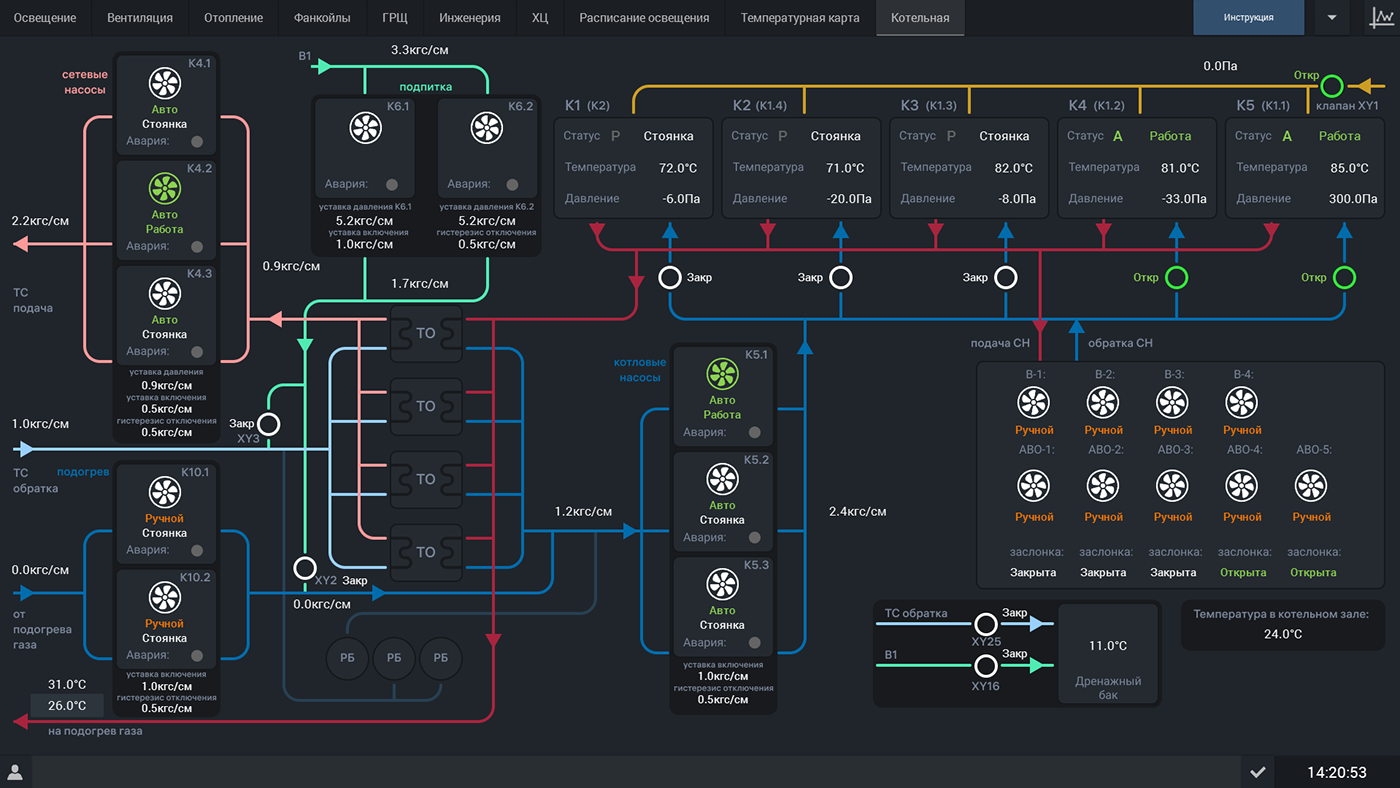

Boiler room

The boiler room had its own automation, it was in-service, so we didn't have any will to disturb it. Yet we had to do BMS somehow.

The interface turned out to be quite intense, however, we do take out a lot of data.

Modernization of individual heating unit

We decided to fully modernize one heating unit though, and to change the control panel completely. The existing automation didn’t allow for management from the control room, and it was very important for operation, they wanted to change set points, the schedule and manage the shafts and pumps. We designed a new control panel based on Segnetics SMH4, assembled everything, mounted, connected and launched it. We reworked the interface in scada, and added management and schedule.

As a result?

We have done a lot of work for these years. Now we have 16,000 variables in scada, everything is in templets, the windows load and open at once, nothing crashes or lags. The whole work was done by a team of 3 people. For this time period we have remade ventilation, lighting, FCUs algorithms for several times, constantly adjusting and improving something. The facility is very big, that’s why we have enough work to come, it’s a practically endless process.

Thank you for reading till the end, I hope the information will prove useful.